Through its unique offering of state-of-the art blenders and food processors, coffee bars, irons/steamers and vacuum cleaners, SharkNinja has strategically increased its share to 30% of the competitive U.S. household appliance market. The manufacturer, based in Newton, Massachusetts, attributes part of its success to innovative R&D and new product development (NPD) practices.

In particular, SharkNinja has adopted a simulation-driven philosophy in product development. The company uses a combination of analysis tools and techniques to gain a deeper understanding of product behavior, as well as to improve product performance and durability.

Simulation tools from Altair’s HyperWorks® suite help drive engineers’ efforts and keep them focused on the company’s mission: to innovate and deliver the products that positively impact people’s lives every day in every home around the world.

The “Wow” Factor

How does SharkNinja define product innovation? Senior Mechanical Engineer Pu Zhou explains the company relies heavily on customer feedback. Products that garner a “wow” and five-star reviews are definite indicators of external success. Time to market and cost drive internal measures of success.

It takes approximately 18 months for a product to go from concept to the store shelf, depending on the appliance. In the case of vacuum cleaners, the process begins with marketing and industrial design (ID) teams pitching product requirements and functionality. The recommendations are shared with the design team in China, which collaborates with contractors to deliver initial CAD drawings.

Zhou, the R&D and NPD lead, says that engineers employ rapid prototyping technology to produce two to four rounds of prototypes. A cross-functional team then performs multiple evaluations. Engineering and quality team members focus on product functionality while ID and marketing staff make sure the product appeals to customers.

Simulation is heavily involved in the process. In fact, it is the first step in a series of standard practices that Zhou has implemented at SharkNinja.

“We use finite-element analysis (FEA) to simulate standard structures before tooling takes place so that we can identify any problems before they occur,” says Zhou. He adds that before every tool change, they run FEA to help ensure things go smoothly.

A Simulation Mindset

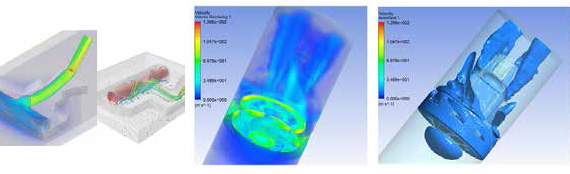

In its product evaluations, SharkNinja performs drop testing, strength and durability analysis, and fluid dynamics simulation. Flow analysis is performed to increase the suction power of vacuums and the mixing effectiveness of blenders.

Zhou explains that the company wants its vacuum cleaners to be sturdy enough to withstand accidental drops or impact occurring during normal usage without mechanical failures or housing cracks. Using Altair’s HyperMesh®, a finite-element pre-processor for modeling complex geometries, and RADIOSS®, a nonlinear structural analysis solver, team members develop detailed simulation models of vacuum cleaner sections and then subject them to various virtual drop test and impact scenarios.

Simulation techniques help product designers and analysts better understand the root cause of potential problems early in the design stage. The software enables them to address design issues without having to build and test models at the point of failure reporting.

For vacuum cleaners, FEA is performed on nozzle, handle and body assemblies. For each assembly, there are different tests performed. “FEA shows potential failure points so that we can change the structure,” says Zhou.

He recalls a recent project in which the team was working to improve the front and side edges of a vacuum cleaner. At issue was the nozzle wall thickness. “We could not perform tests on the prototypes, so we were unable to get any information on structural integrity,” notes Zhou. He did not want to wait until off-tool parts were created because that could result in costly retooling changes and unacceptable program delays.

Instead, the team relied on RADIOSS to simulate the reliability tests. After a few days of running multiple load cases, Zhou was confident that the wall thickness would survive the tests, with some reinforcing efforts.

While analysis tools are used in product development, they also play a role in SharkNinja’s quality initiatives. The company’s Continuous Improvement Team handles issues after mass production, often requesting engineering change modifications to products already on the shelf. Zhou collaborates with this team, running simulations before any new tooling takes place.

Last year, for example, the Continuous Improvement Team asked for Zhou’s help to identify an issue with a steam product. Zhou performed drop test simulation and was able to pinpoint the problem in only three days.

Lighter is Better

Whether consumers prefer an upright or canister model, the lighter the vacuum, the better, especially when users have to carry the appliance up and down stairs. That’s why SharkNinja devotes time to lightweighting design initiatives.

One of the initiatives includes in-house user testing, for which the company invites consumers to participate. If SharkNinja receives feedback that an appliance is perceived as too heavy, it shifts into evaluation mode.

Zhou explains that the base of a vacuum cleaner holds most of the components and is the heaviest assembly. The opportunity to make a vacuum cleaner lighter lies in the nozzle assembly.

To cut down on weight, SharkNinja evaluates different nozzle head shapes. “We remove and even change material,” says Zhou. “FEA helps, as we need to make the nozzle light but strong enough to survive the tests.”

Improving Efficiency

A key component in vacuum cleaners is the fan, and high efficiency is critical to operations. Zhou recalls one project in which the team investigated ways to improve product motor fans with the use of computational fluid dynamics (CFD) software. AcuSolve®, a CFD solver within the HyperWorks suite, provided the thermal and flow analysis capabilities.

Zhou relates that the team needed to evaluate a lot of parameters in the fan design, including blade thickness. However, they were not sure which parameters to alter.

“By using CFD,” says Zhou, “we did not have to create a prototype. We built meshes and ran them to get our results. And the results correlated with testing.”

With AcuSolve, analysts do not have to build a very structured mesh, which saves time in the model preparation phase. Ease of use and speed are reasons for its increasing adoption at the company.

Keeping Costs in Check

SharkNinja is constantly looking for ways to operate efficiently in its NPD process. To help keep costs low, SharkNinja relies on global contractors with different skill levels to provide CAD models; however, the models are often in need of repair before analysis can take place.

Simulation tools in the HyperWorks suite, such as SimLab®, help address this issue. SimLab automates simulationmodeling tasks to reduce human errors as well as cost and time spent manually creating finite-element models and interpreting results.

SharkNinja also takes advantage of Altair’s HyperWorks licensing system. The company purchases an annual subscription license for a “pool” of HyperWorks Units (HWUs); each HyperWorks application draws a specific quantity of HWUs that are returned to the pool when the application is closed.

SharkNinja has engineering resources in China, the United Kingdom and India. The HyperWorks licensing model delivers a comprehensive CAE platform, offering scalability and significant value with a pool of HyperWorks units available to SharkNinja NPD teams in each country where they operate.

According to Zhou, “Altair’s licensing model enables us to use the unparalleled pre-processor SimLab and solver RADIOSS at an attractive cost. It lets us perform multiple analyses simultaneously — and fast — and lowers our costs.”

He adds that Altair’s Compute Manager service — which enables users to set up, submit, and monitor jobs on distributed resources — enables the company to run projects with no additional license required.

“The total cost,” says Zhou, “finally becomes lower than the benefits it brings. That’s critical in the cost-sensitive consumer product industry.”

Innovative Decisions

SharkNinja’s innovative decision to adopt simulation technology in its NPD process — and make it a global standard practice — has strategically propelled the company to success.

The R&D team can perform more virtual tests of different designs to see how they perform. Team members have been able to change the cost component of products by simulating performance with different materials. Manufacturing problems also have been averted or prevented through the use of simulation.

The technology allows SharkNinja to allocate its resources more efficiently as well as discover opportunities for product improvement early in the design process, when changes are cost-effective.

Zhou sums up, noting that the simulation tools — as well as support from Altair engineers — make a difference in global SharkNinja product development: “Simulation and Altair Hyperworks boost our capability to positively impact people’s lives every day in every home around the world.”

SharkNinja Works Hard at Being a Household Name

SharkNinja’s roots date back more than a century. The company originated in Europe, then moved to Canada. Its headquarters are now outside of Boston.

Previously known as Euro-Pro, the company made a name for itself through its Shark® and Ninja® products. In July 2015, Euro-Pro changed its company name to SharkNinja to establish one unified identity — and to capitalize on the awareness, consumer trust and success of each brand.

The company prides itself on innovation, ease of use and competitive pricing. Its line of vacuum cleaners and household appliances are distributed through major big-box retailers, specialty stores and its websites.

SharkNinja reports annual revenue of $1.6 billion dollars. Recent recognitions include being ranked the “Highest in Customer Satisfaction with Upright Vacuums” by the J.D. Power 2015 Vacuum Satisfaction StudySM.